VACUUM THERMOFORMING

Vacuum thermoforming is a manufacturing process used to create plastic parts. In this process, a thermoplastic sheet is heated to a pliable temperature and then stretched over or into a mold or pattern. A vacuum is applied between the mold surface and the plastic sheet to ensure a precise fit. Vacuum thermoforming offers a cost-effective alternative to injection molding, featuring distinct advantages such as lower tooling costs, high-volume replication, and remarkable versatility.

At our facilities in Naples, Florida, and offshore, we have robust plastic thermoforming capabilities. Both locations produce high-quality, durable products that are not only aesthetically pleasing but also built to last.

If you’re in search of a reliable manufacturer with advanced vacuum thermoforming capabilities, contact Globalink Manufacturing Solutions today!

Trusted By Industry Leading Companies

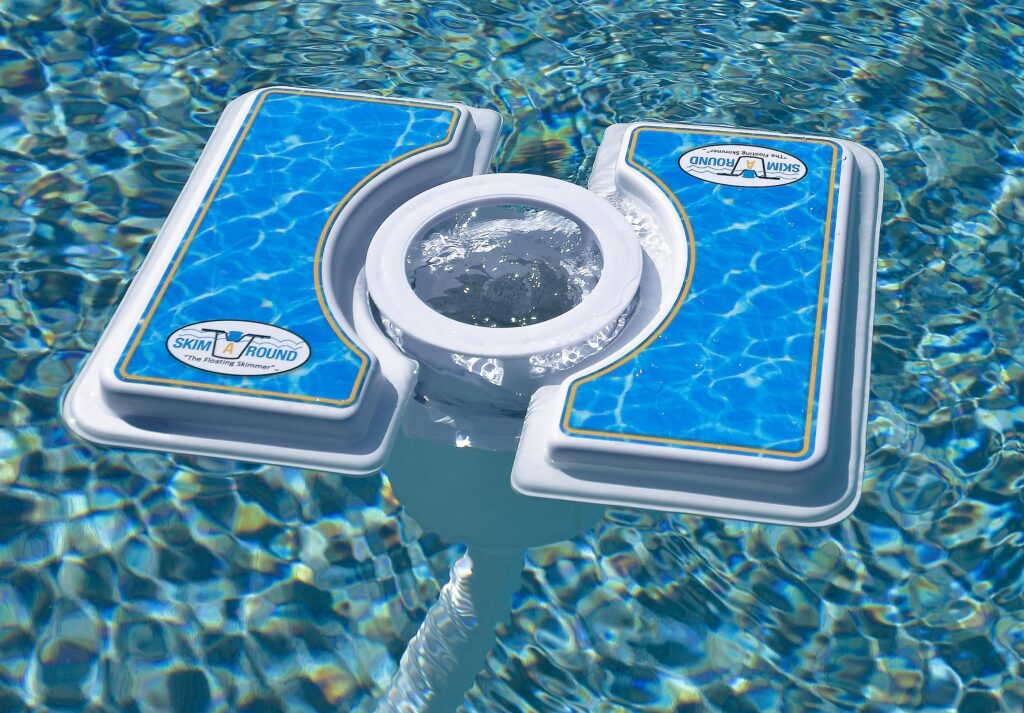

- Enclosures

- Signs

- Covers

- Trays

- Packaging

- Pans

- Bucket

- Blisters

- Guards

- Point Of Purchase Displays

- Housings

- Planting Trays

Substrates Utilized

- ABS

- PC/ABS

- HDPE

- TPO

- HIPPS

- Acrylic

- PET

- Polypropylene